A Study on FSA Application for Human Errors of Dynamic Positioning Vessels Incidents

Article information

Abstract

Formal Safety Assessment (FSA) has been mostly implemented on the hardware aspects of vessels. Although there are guidelines regarding human error FSAs, there have not been many assessments in such areas. To this end, this study seeks to use precedent studies for the safe operation of DP vessels, conducting an FSA regarding human error of DP LOP (Loss of Position) incidents. For this, the study referred to precedent studies for the frequency of DP LOP incidents caused by human errors, adding the severity of LOP incidents, and then applying them to the Bayesian network. As a result, the study was able to confirm that among DP LOP incidents caused by human errors, the drive-off from skill-based errors was 74.3% and the drive-off from unsafe supervision was 50.5%. Based on such results, RCOs (Risk Control Options) were devised through a brainstorming session with experts coming up with proposals including providing mandatory DPO training, installing DP simulator on the vessels, drawing up measures to understanding the procedures for safe operation of DP vessels. Moreover, it was found that mandatory DPO training is reasonable in terms of cost benefits and that while installing a DP simulator is not suitable in terms of cost benefits, it can significantly reduce risks when operating DP vessels.

1. Introduction

The Formal Safety Assessment (FSA) has been frequently conducted on a merchant vessel’s hardware according to the IMO guidelines but rarely on human errors. Regarding the analysis of human errors in marine affairs, Rothblum et al. proposed an effective program for the evaluation of incidents including human factors(Rothblum et al, 2002). Moreover, Griggs proved that the Human Factor Analysis and Classification System (HFACS) was a useful tool to analyze human errors in marine incidents by applying the HFACS and analyzing human errors based on a marine incident report of the U.S. NTSB, Canada’s TSB, and UK’s MAIB, respectively(Griggs, 2012). Also, Hauff applied the HFACS to human factors in the loss of position (LOP) incidents of dynamic positioning (DP) vessels and analyzed the impact of human errors on DP LOP incidents (Hauff, 2014). In Korea, the method of employing the HFACS and the Bayesian network to control human errors was proposed on the basis of relevant research on human errors in DP LOP incidents.

In the existing case analyses of DP LOP incidents, the 10-year average of LOP incidents caused by human errors was 11.8%, relatively less than the that of other causes(Chae, 2015). However, the author examined 612 reports that had been analyzed in the existing studies in detail and found that human errors were direct or indirect causes of 61.2% (375 cases) in LOP incidents.

In this paper, based on the analysis, the FSA is conducted on human errors in DP LOP incidents for the safe operation of DP vessels. To this end, the author aims to quantify major causes of human errors by applying the HFACS and the Bayesian network provided in previous studies to human errors in DP LOP incidents, examine the impact of human errors on DP LOP incidents, and propose the risk control options (RCOs) to mitigate human errors based on a cost-benefit analysis.

2. Premise and Tools of Research

2.1. Research Premise

The reports of DP LOP incidents that occurred from 2001 to 2010 do not include human injury, collision and property damage. Therefore, in the paper, the FSA is conducted based on the causes of DP LOP incidents caused by human errors and the severity by incident types.

This paper, the FSA is only conducted on 103 DP LOP incident reports which officially identified human errors as the primary and secondary causes of LOP incidents, considering that the analysis of DP LOP incident reports may affect credibility. The types of DP LOP incidents caused by human errors are as in Table 1 with reference to previous studies(Hauff, 2014).

2.2. Tools Used in the FSA

2.2.1. Brainstorming

Five individuals including the author, two DPOs, a DP vessel supervisor, a Dynamic Positioning Operator (DPO) instructor and an Fail Mode and Effect Analysis (FMEA) expert carried out two rounds of brainstorming in order to determine the following:

A. Identifying the RCOs for human errors and decide its priority;

B. Deciding on the amount of reduced risk by applying the RCOs for human errors.

2.2.2. HFACS and Bayesian Network

The HFACS on 103 DP LOP incidents caused by human errors was classified based on previous study(Chae, 2015). Furthermore, in order to identify the prior probability and conditional probability of human errors, the Bayesian network flow chart of LOP incidents caused by human errors was created based on the incident types categorized in Table 1. The MS excel data on the occurrence and non-occurrence of incidents was analyzed with GeNIe, which is a useful program that graphically displays prior probability and conditional probability by reflecting incident data in the flow chart created based on qualitative analysis(Bayesfusion, 2015).

3. FSA Application

3.1. Risk Identification

3.1.1. HFACS Classifications

The HFACS classification of 103 cases of human errors in previous study has shown that all human errors of DP LOP incidents occurred due to unsafe acts. And, 40 cases attributable to precondition for unsafe acts (38.8%), 88 cases to unsafe supervision (85.4%), and 68 cases to organizational influences (66.0%)(Chae, 2015). The means of % in this study is that 103 human errors are considered as 100%, and the percentage of individual human errors is expressed as % which allowed duplication application. Out of the causes of 103 DP LOP incidents caused by human errors, in terms of organizational influences, the inadequacy of established procedures was highest with 54.4%, and the inadequate management of human resources stood at 32.3%. In terms of unsafe supervision, the inadequacy of operational procedures or plans was found to be the biggest cause with 37.5% and the failure to provide oversight was 28.4%. In addition, in terms of the precondition for unsafe acts, a lack of knowledge was highest with 35%, followed by distraction of 20%. Lastly, In terms of unsafe act, skill-based errors accounted for 68.9%, followed by decision errors of 27.2%(Chae, 2015).

3.1.2. Frequency Analysis of Human Errors

The risk is expressed as multiply of severity and frequency.

The criteria on the severity of DP LOP incidents caused by human errors was established as in Table 2 (Chae, 2016). And, the criteria on the frequency of human errors was established at five stages as shown in Table 3. The severity referred to the DP LOP categorization of table 1. And, frequency is predetermined criteria based on DP LOP incidents report of IMCA. Accordingly, the risk index on unsafe acts was created as provided in Table 4.

Fleet at risk is calculated as follows :

A. 365 × 0.7(Operation rates per year) × 0.7(DP Operation rates within Operation rates) = 178.85(days)

B. 38,840 DP vessels(total vessel numbers during 10 years) × 178.85(days) = 6,946,534(days)

C. 6,946,534(days) ÷ 365(days) = 19,032 DP vessel year(IMCA, 1994)

The value of the risk index for each human error caused by unsafe acts in Table 4 can be calculated by identifying the frequency of HFACS-classified human errors and applying the result to Table 2 and Table 3. It indicates that the most dangerous factors in human errors are drift off and drive off caused by skill based errors.

The frequency of human errors caused by unsafe act in Table 4, divided by the severity (SI) of drive off, operation abort and time loss, results in the frequency of human errors caused by unsafe acts by LOP incident types as in Table 5. It was found that the highest risk of DP LOP incidents caused by human errors is drive off resulting from skill-based errors and decision errors (RI 7), followed by drive off (RI 6) resulting from perceptual errors.

3.2. Risk Analysis

3.2.1. Cumulative Frequency and F-N Curve

In order to draw the F-N curve, the cumulative frequency of each human error of drive off, operation abort and time loss is calculated as in Tables 6-8. Cumulative frequency is cumulative frequency of each human errors as it says. A calculation method is shown in Table 6.

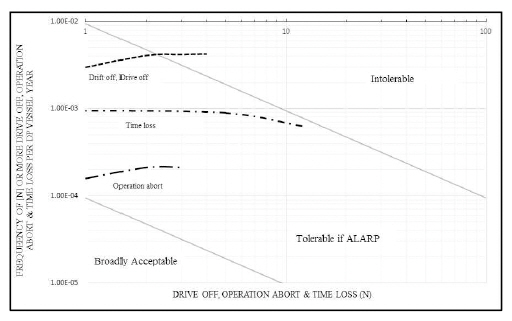

Fig. 1 shows the F-N curve based on Tables 6-8. Since DP LOP incidents analyzed in this study do not include deaths, property damage and environmental damage, the average value of cumulative frequency of drift off, drive off, operation abort and time loss was applied on the ALARP boundary of the F-N curve. Therefore, the author would like to clarify that the boundary does not refer to social and individual risks but sets the average frequency of DP LOP incidents caused by human errors as the broadly acceptable criteria.

As Fig. 1, parts of drift off and drive off are beyond the tolerable boundary of ALARP. The ALARP boundary in Fig. 1 does not indicate the broadly acceptable criteria. Therefore, it does not translate into the idea that the risk of the part exceeding the ALARP should be reduced regardless of costs, but the risk of LOP incidents caused by human errors should be reduced in a reasonable method. Risk factors in human errors identified in the frequency analysis are provided in Table 9.

3.2.2. Analysis of Bayesian Network

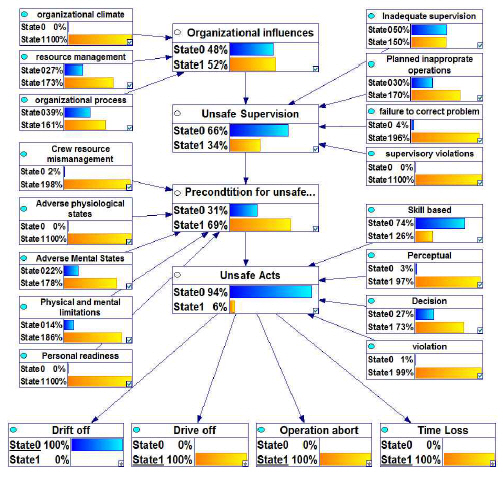

A flow chart of DP LOP incidents caused by human errors was created with GeNIe based on the HFACS analysis. And, 103 LOP incidents were organized into a MS excel file. Then, the file was run on GeNIe and the prior probability of drift off, drive off, operation abort and time loss was calculated as in Fig. 2.

The probability of drift off was found to be 41%, drive off to be 38%, operation abort and time loss to be 11% and 25%, respectively.

Futhermore, the sensitivity of DP LOP incidents was examined with GeNIe, and it was found that skill-based unsafe acts were the most sensitive factors for drift off, drive off, operation abort & time loss as shown in Fig. 3. In terms of the precondition for unsafe acts, physical and mental problems had the biggest impact.

Also, the conditional probability of drift off, drive off, operation abort and time loss was examined based on Fig. 2, and one of the result of the conditional probability for drift off is shown in Fig. 4.

As in Fig. 4, when conditional probability is examined with probability of drift off 100%, the causes of human errors in drift off were identified as unsafe acts (94%), preconditions for unsafe acts (31%), unsafe supervision (66%), and organizational influences (48%). In this regard, DP LOP incidents that have occurred in the past decade can be mainly attributed to drift off caused by unsafe acts. Moreover, human errors caused by unsafe acts were mainly due to the absence of appropriate supervision and inadequacy of established procedures rather than a lack of operators’ mental readiness, physical constraints, and a lack of preparation. Such results are similar to those of the above frequency analysis of incidents.

So far, the frequency analysis based on the HFACS and the Bayesian network were conducted on 103 DP LOP incidents caused by human errors. The factors that mainly affect DP LOP incidents were found to be as in Table 10.

The biggest cause of LOP incidents caused by human errors is skill-based human errors, which are highly affected by inadequate supervision and organizational influences.

3.3. Risk Control Methods

The triangle of effectiveness is applied to control risks of human errors identified in the HFACS and the Bayesian network. Created based on the HFACS, it models 8-step measures to prevent or reduce human errors and the impact of each measure as in Fig. 5(Rothblum et al., 2002).

Out of the 8-step factors, the biggest factors that affect risk control are policies, culture and workplace design. Therefore, it would be effective to propose changes in such parts with regard to the RCOs for human errors.

With reference to such findings, brainstorming was used to determine the RCOs to prevent or reduce risks of human errors identified in the HFACS classification and the Bayesian network as in Table 12. The RCOs for brainstorming were created in advance and proposed in a meeting, and the agreement was sought on proposed RCOs. It is inefficient to apply all RCOs agreed upon in brainstorming. Therefore, the priority of RCOs was set as in Table 11 based on expert concordance coefficient, considering items found to be highly risky in the frequency analysis and major human errors identified in the Bayesian network.

In terms of expert concordance coefficient, the formula on concordance coefficient level provided in MSC 83/INF. 2 was used(IMO, 2007). The formula is as follows.

W = experts concordance coefficient

J = experts in total

I = scenarios

In terms of the expert concordance coefficient W on each RCO codes, RCO A stood at 0.78, RCO B at 0.91, RCO C at 0.88 and RCO D at 0.83. According to the IMO guidance, concordance coefficient of W > 0.7 is considered adequate(IMO, 2007). Out of the proposed RCOs, all experts agreed that if DP simulators (B6, D1, D3 and D4) are installed on a vessel, risks of human errors can be reduced in various ways.

For Table 11 and 12, the RCOs related to policies and organizational culture were mainly selected, and they can be classified into eight factors of the triangle of effectiveness as shown in Table 13.

Experts agreed that the application of proposed RCOs may reduce risks as follows.

A. RCO A1: Since 30% of DPOs get on board without a DPO certificate issued by the NI, mandatory DPO training may reduce risks by 30%.

B. RCOs A4 and B1: Updating the DP operational procedures that continue to be established in the industry and raising awareness of DPOs on such procedures may reduce human errors by 20%.

C. RCOs B2: Since a number of human errors are attributable to unsafe supervision, adequate supervision of DP operation may reduce risks by 30%.

D. RCOs B5: The professional system on the DP operational procedures may reduce risks by 30% (It refers to professional DP operational procedures different from those provided in the RCO A4)

E. RCOs C1 and D2: While monitoring is already conducted in the operation of DP vessels, considering that 20% is perfunctory, more thorough monitoring by a supervisor may reduce risks by 20%.

F. RCOs D1, D3 and D4: It was agreed that getting accustomed to the tasks through task simulations using simulators installed on the main vessel in advance would be effective and may reduce the frequency and risk of human errors by 50%.

G. RCOs A2, C2 and C5: The continuous evaluation of DPO’s capabilities and training on recognizing situations, making decisions and managing bridge resources may reduce risks by 20%.

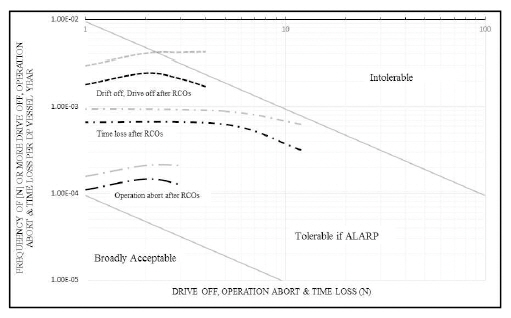

The amount of risk reduced by proposed RCOs is shown in Table 14. The F-N curve based on the agreed amount of reduced risk is shown in Fig. 8. However, since there is a limit to reducing human errors by brainstorming due to its qualitative nature, further research on quantification is invited in this regard.

In Fig. 6, it was found that applying the proposed RCOs can have drift off and drive off within the tolerable if ALARP boundary. This means that the proposed RCOs are reasonable measures to reduce the frequency of DP LOP incidents caused by human errors. Considering that there can be deviation in the brainstorming results of experts, in terms of applying the proposed RCOs, the simultaneous application of a number of RCOs can basically maximize the amount of reduced risk. For instance, installing DP simulator can enable the simultaneous application of training on prior simulations (50% reduction), training on emergency response (20% reduction), training on better decision making (50% reduction), and training on skill-based errors (50% reduction), thereby reducing the risk of DP LOP incidents caused by human errors by 50% or more based on expert opinions.

F-N curve after apply RCOs(Chae, 2016)

3.4. Cost-benefit Analysis

The GCAF is applied to identify cost benefits of the proposed RCOs(IMO, 2007). Since costs are not incurred the proposed RCOs except for the RCOs A1 and D1, the cost-benefit analysis is only applied to the RCOs A1 and D1. The cost-benefit analysis was conducted as follows.

A. The expected amount of reduced risk from mandatory DPO training through brainstorming was applied at 30%.

B. The expected amount of reduced risk from installing DP simulators through brainstorming was applied at 50%.

C. The costs for installation and maintenance of simulators were identified by DPS manufacturers (△C, the costs incurred from the application of the RCOs, will be calculated with the NPV)(IMO, 2007).

D. The GCAF on the RCOs was calculated(IMO, 2007).

In this case,

ΔR = Amount of reduced risk throughout the use of simulators

ΔPLOP = Amount of reduced the risk of potential DP LOP incidents after the application of RCOs

Xt = Costs or benefits during time t when RCOs were applied

A = Initial costs for the application of RCOs

r = Depreciation costs (10% is applied to simulators and the costs are not applied to DPO trainings)

T = Period during which DP simulators can be used (10 years) or the effective period of DPO training (5 years)

3.4.1. RCO A1

If mandatory DPO training is required in accordance with the STCW Convention, training expenses are identified at USD 10,000 per person, and there are no maintenance costs or depreciation costs. Based on the information, the cost-benefit analysis was conducted, and as a result, the GCAF was identified at USD 1,234,568 as in Table 15.

According to the IMO guidance, the GCAF of USD 3,000,000 US$ or less is considered to be cost effective(IMO, 2007). Therefore, mandatory DPO training is reasonable in terms of cost benefits.

3.4.2. RCOs D1, D3, D4

The initial installation cost of DP simulators was identified at USD 1,000,000 by manufacturers, and 1-year maintenance costs at USD 10,000, and depreciation costs at 10%, respectively. Accordingly, the cost-benefit analysis on the installation of DP simulators was conducted, and as a result, the GCAF was identified at USD 20,717,552.

The GCAF on the installation of DP simulators is effective in reducing risks in that it exceeds USD 3,000,000. However, in terms of cost benefits, ship owners should make reasonable decisions on installing DP simulators.

3.5. Recommendations

Based on the FSA conducted on human errors in DP LOP incidents, the recommendations to reduce such errors are as follows(Chae, 2016).

A. Mandatory DPO trainings (RCO A1) : DPO trainings are recommended under Section B-V/f of the STCW Convention. Therefore, relevant trainings should be made mandatory in accordance with the “requirements for education and training on crews boarding specific vessels” in Section A-V of the STCW Convention

B. Installation of a DP simulator (RCOs D1, D3 and D4) : DP simulators should be installed on a main vessel for task simulations in order to reduce the risk of potential incidents in the actual operation

C. Awareness and update of the procedures on safe DP operation(A2, A4, B1, B2 and B5)

4. Conclusion

This study conducted the FSA based on the HFACS and the Bayesian network on DP LOP incidents caused by human errors for safe operation of DP vessels, and the conclusions are follows

First, the conditional probability of drift off and drive off caused by skill-based errors was the highest with 74.3%, respectively, and the conditional probability of drift off, drive off, operation abort and time loss caused by unsafe supervision was also high with 50.5%. Therefore, it was found that skill-based errors and unsafe supervision are highly likely to result in incidents.

Second, the F-N curve based on the frequency analysis and the Bayesian network shows that parts of drift off and drive off are beyond the reasonably tolerable risk of LOP incidents caused by human errors. In order to reduce the risk of DP LOP incidents caused by human errors, the RCOs were proposed including providing mandatory DPO training in accordance with the STCW Convention, installing DP simulators, drawing up measures to understanding the procedures for safe operation of DP vessels, updating the procedures. Furthermore, it was found that the application of proposed RCOs reduced the risk of LOP incidents caused by human errors by approximately 50%.

Third, as a result of applying the agreed RCOs, it was proven that the drift off and drive off were within the acceptable range on the F-N curve. Moreover, out of the proposed RCOs, it was found that mandatory DPO training is reasonable in terms of cost benefits, and that while installing DP simulators can significantly reduce risks.

Fourth, the HFACS and the Bayesian network were found to be useful tools for the risk analysis of incidents caused by human errors in the FSA on human errors.

In addition to this study, much research should be conducted on establishing the criteria for social and individual risks in order to determine the acceptable range of risks on the F-N curve, and applying vessel incidents caused by human errors to various types of vessels.

Acknowledgements

This paper is based on dissertation thesis of Chong-Ju Chae, titled ‘An Application of FSA for Safe Operation of Dynamic Positioning Vessels’