Communication Failures During Chemical Tanker Cargo Operations

Article information

Abstract

Chemical tankers handle a diverse range of cargo types, necessitating varied cargo handling procedures due to the hazards associated with each type. Consequently, operations require heightened precautions and attention. Any misinterpretation or oversight can result in irreversible accidents. The incidence of cargo overflow in prior chemical tanker operations was reported by 56.09% of 353 Turkish, Korean, and Indonesian participants in this study, substantiating the gravity of the matter. In this study, the variables that caused communication failure during cargo operations and countermeasures are discussed in detail. The analysis leveraged survey data processed using factor analysis via SPSS. All of the top five factors leading to communication failure were attributed to human errors. Notably, unfamiliarity with cargo operations emerged as the most prevalent cause of communication failures, and stopping a blaming culture was the first among the countermeasures. The identified causes of communication failures could be solved by the countermeasures suggested by the survey participants. The solutions will promote effective communication during hazardous cargo operations and subsequently contribute to safety with significant potential to provide valuable insight into companies operating a fleet of chemical tankers.

1. Introduction

Maritime transportation holds a pivotal position in the global economy, representing nearly 90% of worldwide goods transport (Jiang et al., 2020). Chemical tankers must adhere to specific handling loading/unloading, and operational safety requirements when transporting various categories of chemical liquids, these requirements encompass distinct conditions and safety measures (Arslan et al., 2008). Risk analysis holds paramount significance in the realm of chemical tanker cargo operations to ensure safety. Troughout the various stages of chemical cargo operations, including loading, discharging, tank cleaning, ventilation, and cargo condition monitoring, a complex web of interactions between humans and systems becomes evident. To prevent catastrophic incidents in chemical tankers, it is imperative to swiftly implement strategies and promptly execute decision-making protocols within the framework of operational management (Celik, 2010). Hazardous cargo, under particular conditions and vulnerabilities and at specific levels, can potentially lead to leaks, releases, fires, and explosions (Saruchera, 2020). Hence, it is imperative that the crew maintains a constant awareness of cargo-related information and is well-versed` in the necessary procedures to follow in the event of an accident (Ung, 2019). Effective communication, being an inherent component of participatory processes, plays a central role across diverse operational domains (Stranks, 2007). According to an accident report published by Isle of Man Ship Registry (2001) on Cargo Tank Explosion of Emilia Theresa. The explosion that occurred in the Brazilian port of Santa Clara during Benzene loading underscores two key recommendations: enhancing supervision and improving communication between ship and terminal. For this cause, it is indispensable to ensure the highest level of communication efficiency during the chemical tanker operation. Communication failure can be characterized as a deficiency in the content, intended audience, contextual setting, or fundamental purpose of the communicative endeavor (Braaf et al., 2011). Successful communication of risks and hazards is the best way to prevent accident, oil spill as well as injury (Razmjooee, 2012.). In this paper, Cargo operation risk analysis is only superficially emphasized communication failures encountered during chemical tanker cargo operations and ways to prevent them are analyzed in 3 steps. In contemporary times, chemical tanker enterprises have placed a heightened emphasis on the integration of risk analysis within their operational frameworks. This strategic shift is necessitated by the diminishing duration of port stays and the expanding diversity of cargo, demanding a thorough and comprehensive examination of each individual concern. In this way, it has shed light on the root causes of what is referred to as communication failure in human factor analysis. The first step was determination of communication failure variables and Risk Control Options (RCOs) through expert survey, the second step was conducting a Likert-scale survey to rank the given variables by including participants with work experience onboard chemical tankers and the last step was conducting data analysis using Statistical Package for the Social Sciences (SPSS) 28.

1.1 Problem Statement

In present-day maritime operations, the reduction in port duration for ship activities necessitates heightened vigilance and precautionary measures when handling various kinds of chemical cargoes. In inverse proportion to such a decrease in time, the documents to be filled have increased. According to Güzel et al., (2023) concurrent operations like various ship inspections and miscellaneous supply operations tasks transpire alongside cargo handling. A total of 37 participants were involved with assessing communication network density within four distinct scenarios pertaining to chemical tanker cargo operations. The evaluation was conducted using a Likert scale-5, a commonly utilized scale in survey research for participants to express their perspectives and perceptions in a structured manner. The outcomes were visually represented and analyzed utilizing Gephi, a robust tool utilized for conducting social network analysis (SNA). The communication weights as scenario in Fig. 1 is a situation where there are parcel cargo operations, service companies and also an inspection. The inspection may be one or more than one, Classification Society, Flag State, PSC (Port State Control), SIRE (Ship Inspection Report Programme), Safety Radio and Safety Equipment inspections. STS status is also taken into consideration.

Executing numerous tasks within a limited timeframe significantly amplifies the risk of errors. Consequently, in order to guarantee the safe execution of hazardous tasks, optimizing communication becomes imperative. This study addresses communication challenges during cargo operations, delineating prevalent issues and analyzing corresponding mitigation strategies.

2. Methodology

2.1 Literature Review

In the study conducted by Aydin (2021), the methodology section employed expert judgments to evaluate the potential risk of cargo leakage in oil/chemical tanker ships. The process involved initial identification of variables, followed by subsequent rounds of evaluations conducted in collaboration with experts to determine the outcomes. The study also utilized Fault Tree Analysis (FTA) to assess fundamental events and analyze their influence on the probability of the top event.

Khan (2022) studies explores human factors in hazardous cargo port operations, offering insights for port safety and maritime transportation. The methodology involves expert judgment and literature review. Key variables contributing to hazardous cargo port accidents are safety concerns, inadequate supervision, cognitive issues, and rule violations. The study highlights that errors and violations significantly increase the accident risk probability. Sensitivity analysis underscores errors and violations as critical factors, leading to a 48.2% change.

In the study by Şakar & Zorba (2017) a risk analysis was conducted for oil/chemical tankers during hazardous cargo operations. The research utilized the Fuzzy Bayes Network Method to create a model aimed at preventing potential accidents in these operations. Key factors contributing to fire and explosion risks during tank cleaning were identified as ignition sources, reaction potential, and safety culture. The study's findings hold practical implications for enhancing the safety of oil/chemical tanker operations. The variables central to the issue, forming the graphical structure of the Bayes Networks, were determined based on expert opinions.

Numerous studies have delved into risk analyses within the realm of chemical tanker cargo operations. However, a dedicated study focusing specifically on communication within this context is notably absent. As a result, additional research was carried out, exploring articles that discuss communication failures across different domains.

Vieira et al., (2014) comment that " The International Civil Aviation Organization (ICAO) encourages all professionals, in any situation, to listen, think and speak" (p.133). In order to avoid communication failure during the flight, it's essential that active listening should be introduced early at the stage of training to controllers and pilots so that they are able to identify the small details that can transform such failures into assertiveness rather than catastrophes.

Wanjari (2019) describes the lack of communication skills, lack of credibility of the feedback giver, fear of upsetting colleagues or students, lack of confidence, personal agendas, physical barriers, and students' resistance while receiving feedback as the barriers in the way of giving feedback in the context of medical education.

Parke, Hobbs & Kanki (2010) argue that "shift handovers occur in many safety-critical environments, including aviation maintenance, medicine, air traffic control, and mission control for space shuttle and space station operations." Such handovers are generally linked with the risk of communication failures and human error.

McCabe & Healey (2018) argue that, given that misunderstanding and miscommunication are particularly problematic in psychosis, this is critical for improving the longer term outcomes of treatment for these patients who often have poor relationships with psychiatrists and health care services more widely.

Eaton (2017) mentioned that in many areas of clinical and academic medicine, bias has been produced as a result of the medical hierarchy. It could be argued that medical hierarchy is a barrier in the way of communication in the medical field and discourages any kind of communication taking place among the medical staff.

2.2 Expert Opinion

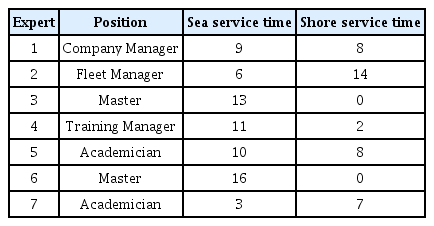

To identify the communication failures encountered during cargo operations and the encounter measures, we have received expert opinions shown in Table 1. The expert opinions were determined through brain storming with the selected experts.

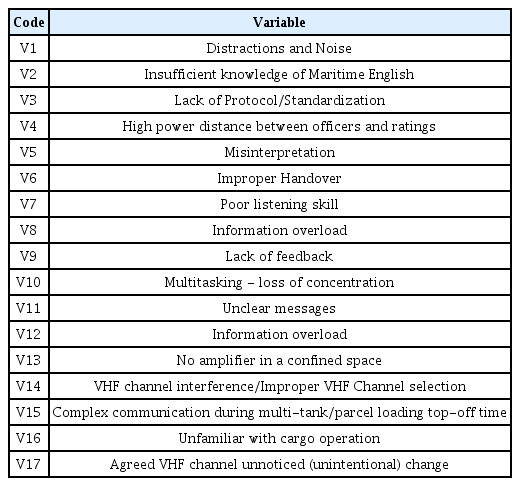

After the acquisition of expert opinions, a total of 17 communication issues impacting cargo operations and 17 RCOs to mitigate these challenges were identified, as delineated in Table 2 and 3.

2.3 Design of the Likert-Scale Survey

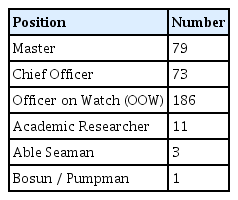

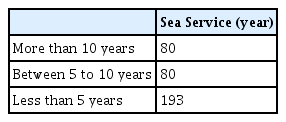

Likert scales offer a convenient method for assessing constructs that are not directly observable. Published tutorials elucidating the development process of these scales have exerted a significant influence (Jebb vd., 2021). The Likert scale is typically structured as a 5-point continuum, spanning from "Strongly Disagree" at one extreme to "Strongly Agree" at the other, with "Neither Agree nor Disagree" positioned in the middle. Nevertheless, certain experts argue in favor of utilizing 7 or 9-point scales, providing added levels of granularity (Harpe, 2015). An online questionnaire based on 7-point Likert Scale was designed to rank the identified communication failures and RCOs from the expert opinion survey. The questionnaire was shared through Google form or prepared questionnaire form (Prepared for those who have difficulty accessing the internet while at sea) with a total response of 353 participants who have work experience onboard chemical tankers. The survey period was within the months of July to mid-September 2023. The details of the participants are given in Table 4. At the outset of the survey, participants indicated their roles and their years of seafaring

The details of the participants sea service years are given in Table 5.

2.4 Analysis of Survey

In the context of factor analysis, it is a common recommendation to employ the sample-to-item ratio as a determinant for the required sample size, which is contingent upon the number of items under investigation. It is generally advocated that this ratio should not fall below 5-to-1 (Suhr, t.y.). As an illustration, when considering a study encompassing 30 items or questions, a sample size of approximately 150 respondents is recommended, maintaining a sample-to-item ratio of 5-to-1. Moreover, an alternative suggestion proposes a ratio of 20-to-1, further emphasizing the importance of an adequate sample size relative to the number of items for robust exploratory factor analysis (Costello & Osborne, t.y.).

3. Survey & Factor Analysis

Over a period of six weeks, individuals who have experience or are currently working on chemical tankers were surveyed using Google Forms or a prepared questionnaire form. After all data is received analyses were carried out in IBM SPSS Statistics 28 and Smart PLS Version 4 package software. The validity and reliability studies of the models were performed using factor analysis in Smart PLS 4 programme. The analysis was applied using partial least squares structural equation modelling (PLS-SEM) The significance level in the analyses was accepted as 0.05.

3.1 Factor Analysis for the Communication Failure Variables

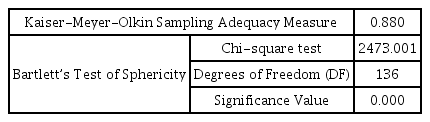

According to Table 6 KMO value is 0.88 and the result of Bartlett's Test of Sphericity is 2473.001 (p<0.05). KMO values between 0.80-0.90 are considered "very good" (Sharma, 1996). Accordingly, it can be concluded that the 353 participants used for analysis for these 17 items are sufficient.

Moreover, for Bartlett's test of sphericity, the chi-square value is significant at 0.05 significance level. It was determined that the statements met the appropriate conditions for factor analysis.

3.2 Factor Analysis for the Risk Control Options

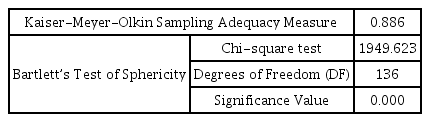

According to Table 7, the KMO value is 0.89 and the result of Bartlett's Test of Sphericity is 1949.623 (p<0.05). Accordingly, it can be concluded that 353 participants used for exploratory factor analysis is sufficient.

In addition, for Bartlett's test of sphericity, the chi-square value is significant at 0.05 significance level. It was determined that the statements met the appropriate conditions for analysis.

3.3 Correlation Test

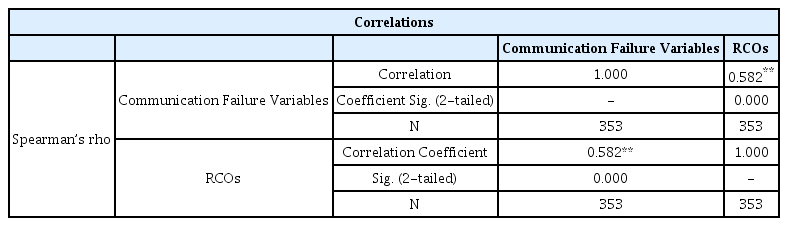

Correlation Coefficient (Spearman's rho): The correlation coefficient is a measure of the strength and direction of the relationship between two variables. In this case, Spearman's rho is used, which is a non-parametric measure of correlation that is appropriate when dealing with ordinal or non-normally distributed data.

Significance (2-tailed): This column indicates the statistical significance of the correlation coefficient. In this table, all the values are marked with "**," which means that the correlation is significant at the 0.01 level (2-tailed). In other words, there is a very low probability (p < 0.01) that the observed correlation occurred by chance.

N: This column shows the number of data points or observations used to calculate the correlation coefficient. In this case, there are 353 data points for both "Communication Failure Variables" and "Encounters.“

The table presents a significant positive correlation (Spearman's rho = 0.582, p < 0.01) between "Communication Failure Variables" and "RCOs" This implies that also tends to increase. The strength of this relationship is moderate (0.582).

4. Results and Discussions

4.1 Statistics According to OOW Perspective

In the study entitled 'Risk Control Options of Communication Failures During Chemical Tanker Operations,' a total of 186 participants, who were identified as Officers of the Watch (OOW), were actively involved. Among these participants 52.69% acknowledged that they had not witnessed cargo overflow during prior cargo operations. The survey revealed that the primary cause of communication failure was attributed to unfamiliarity with cargo operations, leading to a lack of understanding between both parties involved. The second notable reason identified was the inadequate handover during shift transitions. Lastly, participants emphasized the 'lack of feedback' as the third crucial factor, underscoring the potential for communication failures to contribute to accidents due to insufficient feedback. Regarding RCOs, respondents accorded the highest rating to the mitigation of the blaming culture. Recognized for its potential to impede communication either directly or indirectly, mitigating the blaming culture secured the foremost position in facilitating seamless communication. Following closely, the respondents advocated for Risk Control Options, suggesting a need for periodic and enhanced training pertaining to cargo operations conducted by the company. Lastly, assessing maritime English proficiency levels of onboard personnel and assigning them accordingly to the vessel ranked third, emphasizing the importance of language competence in promoting effective communication and safe operations onboard.

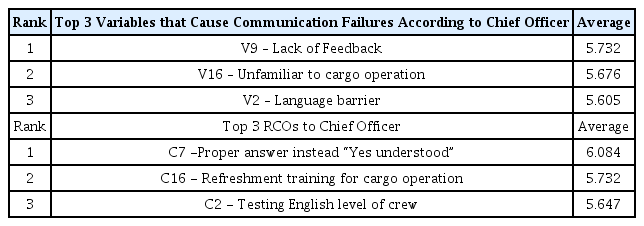

4.2 Statistics According to Chief Officer Perspective

Insights derived from 73 Chief Officers who actively participated in the survey yielded valuable perspective. Notably, a substantial 68.49% of these Chief Officers reported experiencing one or more overflow accidents in their previous operations. As the most authorized of cargo operations, Chief Officers highlighted 'lack of feedback' as the most influential factor contributing to communication failure during operations. They emphasized that timely reporting or lack there of regarding incidents played a crucial role, potentially leading to accidents. Secondly, Chief Officers identified that personnel unfamiliar with cargo operations faced challenges in comprehending the situation, resulting in miscommunication. Thirdly, they indicated that communication failure occurred due to inadequate proficiency in either English or maritime English among the ship's crew. Regarding effective Risk Control Options, the Chief Officers considered 'repeating and confirming the received command' as the most impactful during VHF communications. Instead of simply acknowledging a command, adding 'understood' at the end after repeating the command ensures that both the giver and receiver are certain about the message. In the second position, they recommended training for personnel joining the vessel regarding cargo operations. Lastly, measuring the English proficiency levels of the ship's crew was seen as a crucial step to prevent communication breakdowns before they occur.

4.3 Statistics According to Master Perspective

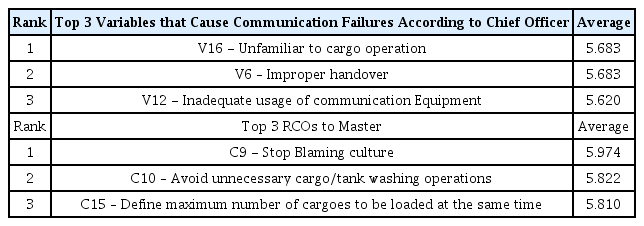

Data were gathered from a group of 79 experienced Masters who willingly participated in the survey. Notably, 64.56% of these skilled Masters recalled instances of cargo overflow in their previous cargo operations. Drawing on years of experience and their position at the helm of ship management, Masters believe that the primary factor leading to communication failure is crew unfamiliarity with cargo operations, ranking it first. Secondly, they pinpointed 'improper handover' as a significant cause of communication breakdown, particularly when the incoming shift crew is unaware of changes in the operation plan or the ongoing phase of the operation. In the third position, they highlighted 'Inadequate Communication Equipment' as a variable. Specifically, they mentioned an issue with the VHF communication, where the initial words are not transmitted to the other end as crew members start speaking before pressing the button. In terms of effective Risk Control Options, they emphasized the importance of halting a blame culture. They noted that fostering crew confidence through a blame-free environment encourages open reporting, thus facilitating healthier communication. In the second position, they advocated for avoiding unnecessary deck cargo and tank washing operations during critical cargo operations. Simultaneously performing multiple operations increases the risk of confusion or misinterpretation during communications, potentially leading to undesired outcomes. Finally, the third Risk Control Options involves the company defining the maximum number of cargos to be loaded simultaneously. Masters, leveraging their extensive experience, have prioritized corrective actions focusing on minimizing risk by advocating for operations to be carried out individually to the extent possible.

4.4 General Statistics

Prior to commencing the survey, all participants were inquired about their prior RCOs with cargo overflow during cargo operations on the vessels they had previously served on. A significant majority indicated that they had indeed experienced such situations. This data underscores the relatively high occurrence of overflow, as indicated by the respondents. In the survey, it was observed that 52.69% of Officers of the Watch (OOWs) had experienced overflow incidents, while this percentage was 68.49% for Chief Officers and 64.56% for Masters. Considering the risks associated with the transported cargoes and the statistical data available, it is evident how serious the situation is.

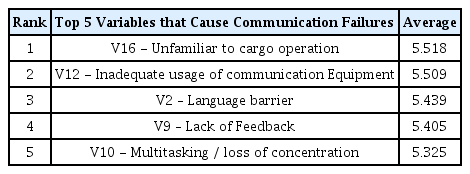

In the Likert Scale-7 scale survey, the participants reported "Unfamiliar with cargo operation" as the most significant issue. In this situation, which they see at the top of the communication failures, although the communication is clear and understandable, incomprehension naturally occurs because the content of the subject is not mastered. In the second rank, the participants stated, "Inadequate communication equipment usage". According to this, the commands from the ship deck to the CCR (Cargo Control Room) or from the ship to the port may not be fully understood because the communication device "VHF" used during the operation is not used correctly. The third rank is "Language Barriers". The issue arising from the presence of a multi-national crew on numerous ships or the lack of technical English proficiency of the crew. The fourth-ranked variable is "lack of feedback". According to this, the two parties that should communicate do not report some situations due to inexperience and overconfidence. The fact that all units are aware of everything in the operation is one of the most critical situations for intervention in any situation. Lastly, fifth-ranked variable ''Multitasking - Lose of concentration''. Accordingly, the increased workload in certain parts of the operation forces the crew to multitask, albeit unintentionally. As an inevitable consequence of this situation, issues may arise due to loss of concentration.

The descriptive statistics for the RCOs were given in table 13 and the top five Risk Control Options were mentioned

The Risk Control Options identified as most effective by the respondents is addressing the prevalent "blaming culture." This item is an indication of how widespread unethical behavior is on board ships. Secondly, in communications during cargo operations, in order to make sure that the message is fully understood by the receiver, the person giving the message should add a short summary of the command or message instead of "understood" and add "understood" at the end. This approach guarantees mutual understanding of the communicated instruction. The third Risk Control Options is related to refreshment training related to the company's cargo operations. Repeating these training sessions before each contract was suggested to be beneficial in terms of maintaining awareness and knowledge. The fourth Risk Control Options involves assessing the crew's proficiency in maritime English. If their language skills do not meet the necessary standard, training should persist until the required competence is achieved. The fifth Risk Control Options suggests postponing non-essential tasks during cargo operations. By doing so, greater attention can be directed towards the cargo operation, mitigating the distraction caused by multitasking and the consequent lack of concentration.

5. Conclusion

The study was initiated with a comprehensive literature review and expert consultations, leading to the identification of 17 communication failure variables and 17 Risk Control Options. These were incorporated into a survey instrument utilizing a Likert Scale-7. The survey was administered through digital means via Google Forms and prepared questionnaire form for limited internet accessibility on vessels. Subsequently, data from 353 participants underwent factor analysis, revealing robust associations between the identified variables and their respective Risk Control Options. Additionally, participants were queried about their past encounters with overflow accidents, with a notable 56.09% reporting such incidents, underscoring the gravity of this issue. The investigation illuminated that communication failure is influenced by diverse factors, with a deficit in cargo operation familiarity, incorrect utilization of communication equipment, language barriers, insufficient feedback, and the strain of multitasking emerging as predominant contributors. Participants underscored the pressing need to mitigate the "blaming culture" as the most efficacious countermeasure, which stands to directly or indirectly enhance communication within cargo operations. Other noteworthy countermeasures encompassed the repetition of understood commands, as opposed to simple acknowledgment, augmenting or offering refresher cargo operation training for crew members, evaluating maritime English proficiency, and prioritizing tasks during peak workloads.

This research presents the potential to provide valuable insights for companies operating fleets of chemical tankers. By addressing the concerns highlighted in safety advisories and maritime training, it is conceivable to substantially enhance safety within cargo operations. Notably, the study primarily engaged ship crew members originating from non-native English-speaking nations, including Turkey, South Korea, and Indonesia. Future research endeavors could extend to encompass personnel on the shore side, such as loading masters and surveyors, and explore various vessel categories, thereby affording a more comprehensive view of safety measures.