A Basic Study on Connected Ship Navigation System

Article information

Abstract

Maritime autonomous surface ships (MASS) has been developed over the years. But, there are many unresolved problems. To overcome these problems, this study proposes connected ship navigation system. The system comprises a slave ship and a master ship that leads the slave ship. To implement this system, communication network, route planning algorithms, and controllers are designed. The communication network is built using the transmission control protocol/Internet protocol (TCP/ IP) socket communication method to exchange data between ships. The route planning algorithms calculate the course and distance of the slave ship using the middle latitude sailing method. Nomoto model is used as the mathematical model of the slave ship maneuvering motion. Then, the autoregressive with exogenous variables (ARX) model is used to estimate the parameters of Nomoto model. Based on the above model, the automatic steering controller is designed using a proportional-derivative (PD) control. Also, the speed controller is designed for the slave ship to maintain constant distance from the master ship. Sea experiments are conducted to verify the proposed system with two remodeled boats.

1. Introduction

Recently, maritime autonomous surface ships(MASS) has attracted much attentions as a game changer in the maritime industry. The International Maritime Organization(IMO) defined MASS as a ship which can operate independently of human interaction and divided the degree of autonomy into four stages at the 99th Maritime Safety Committee in 2018(IMO, 2018).

Because MASS has great advantages from economic point of view, so many researches are actively being conducted in many countries. In Norway, Yara International and Kongsberg developed Yara Birkeland. This vessel was designed to navigate along the coast autonomously and aims to launch in early 2020(Yara International, 2018). The Japanese NYK Line succeeded in the MASS trial performed in accordance with IMO interim guidelines(IMO, 2019). The sea trial was conducted by a car carrier Iris Leader(L : 200 m, B : 34.8 m, GT : 70,826 t)(NYK Line, 2019). The Korean government is planning a MASS project for 6 years from 2020 to develop core technologies(Ministry of Oceans and Fisheries, 2019).

Even if technology reaches the level of autonomous coastal navigation, there are still many problems with hull maintenance, communications, security, emergency response to accident and etc. Due to the above reasons, more time is required to develop a fully autonomous vessel. To overcome these problems, there were researches on a navigation system consisting of a manned vessel and several unmanned vessels.

Hannu, et al.(1998) proposed convoy navigation system and verified by computer simulations and field tests. The convoy system consists of a manned master vehicle and one or more unmanned slave vehicles, and the slave vehicles follow the master according to established rules. Liu and Bucknall(2015) developed an algorithm for the unmanned surface vehicle(USV) fleet navigation and verified it by computer simulations. The fleet is composed of one leader USV and two follower USVs, and the algorithm is designed to follow a planned route, avoiding collisions with other vessels by taking certain formation, such as straight line or triangle.

In this study, authors propose connected navigation system in which one manned master ship leads one or more unmanned slave ships. This system has the advantage that the crew of the master ship can move to an unmanned slave ship using a vehicle, so that it can be solved immediately in case of an emergency. To implement this system, this paper deals with communication network, route planning algorithms, automatic steering controller and speed controller. The system of this research consists of one master and one slave ship as a basic study and is verified its effectiveness by sea experiments.

2. System design

2.1 Communication network

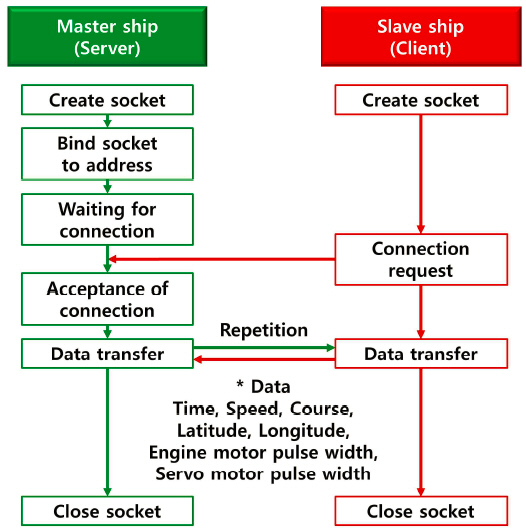

Communication network must be constructed first to design the system, because the slave ship needs to receive position data from the master ship wirelessly to set the route. The transmission control protocol / internet protocol (TCP/IP) socket communication method was used in this study. Fig. 1 shows the communication procedure of the system, the master ship is the server and the slave ship is the client.

The communication procedure is as follows. First, the server and client create sockets. The server binds the IP address and port number to the created socket, then waits for the client to connect. If the client requests a connection to the server, then the server receives the request and accepts the connection. Once connected, the two ships exchange data with each other such as time, speed, course, latitude, longitude, engine motor pulse width and rudder servo motor pulse width. These data are used for the slave ship to set up the route. When the master ship determines that it is no longer necessary to transmit data, the socket is closed to terminate the connection.

2.2 Route planning algorithms

When the slave ship successfully receives the data, the slave ship stores the latitude and longitude of the master ship as a reference point. Then the slave ship calculates the course and distance to the reference point using middle latitude sailing method. If the calculated distance is 5 m or less, the slave ship is considered to have already passed the reference point, and the distance and course to the next reference point are calculated. This process is repeated when the slave ship is underway.

Middle latitude sailing method is based on the assumption that “the departure(p) between two specific points is equal to the arc length of the meridians of the two points at the middle latitude(Lm).”. If the middle latitude is less than 60 ° and the sailing distance(D ) is within 600 nautical miles, the error range is less than 1%.(Yoon et al., 2013).

When the starting point is A (L1,λ1) and the arriving point is Z (L2,λ2) , the course(C ) and the sailing distance (D) between the two points are calculated by Eq. (1) and Eq. (2).

Where difference of longitude DLo, difference of latitude l, middle latitude Lm and departure p are obtained by the following equations.

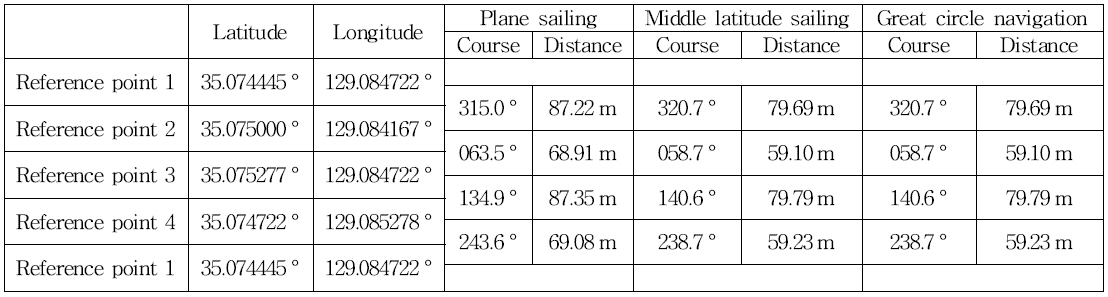

Table 1 shows the results of calculating the course and distance between each reference point using the plane sailing method, middle latitude sailing method and great circle navigation method.

Comparison of plane sailing method, middle latitude sailing method and great circle navigation method.

Although the distance between the reference points is less than 80 m, there was a difference between the plane sailing method and middle latitude sailing method about 5 to 6 degrees on the course and about 34 m on the total distance. Since the plane sailing method assumes the earth as a plane, the theoretical error is large. On the other hand, the calculation results of the middle latitude sailing and the great circle navigation method were almost same. Because the great circle navigation method has high accuracy. But, it has a large amount of calculation and has the disadvantage that the ship’s course should be changed frequently. So, simple calculation but high accuracy middle latitude sailing method was adopted in this study.

2.3 Automatic steering controller

(a) Ship manoeuvring motion model

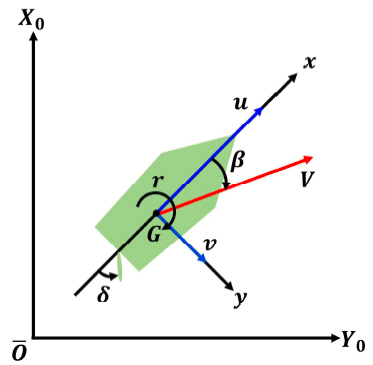

Considering the ship as a rigid body, the ship manoeuvring motion is described for the ship fixed coordinate system(G-xyz) with the coordinate origin at the ship’s center of gravity(G) as shown in Fig. 2.

Where δ is rudder angle, β is drift angle, r is turning rate, u and υ are x-axis speed and y-axis speed, and V is the sum of u and υ. And the ship manoeuvring motion can be formulated as a combined motion by the inertia, propulsion and external forces. On the other hand, the mathematical model proposed by Nomoto et al.(1957) is relatively simple and has the advantage that the slave ship manoeuvring motion could be expressed as a relationship between input(rudder angle) and output(turning rate), not in terms of fluid force. Nomoto model has limitations in representing the motion of the ship accurately. However, the purpose of this paper is to find out the effectiveness of the proposed system using RC boats, so simple Nomoto model was adopted that can predict the manoeuvring motion model of ship with minimal information. And the autoregressive with exogenous variables(ARX) model(Ljung, 1987) was used to estimate the manoeuvring indices K and T, unknown coefficients of Nomoto model. The ARX model generates a transfer function from input-output data, and then estimates the parameters of the transfer function. This method has been used in a study by Kim(2011) to build the USV manoeuvring motion model.

(b) Nomoto model

Nomoto suggested the model expressed by rudder angle (δ), turning rate(r) and manoeuvring indices(T1, T2, T3, K ) shown as Eq. (7).

If T = T1 + T2 - T3 in Eq. (7), Nomoto model can be expressed as Nomoto first order model as in Eq. (8), and the transfer function is as in Eq. (9).

(c) ARX model

Since the ship is constantly moving, the ship manoeuvring motion should be handled on a continuous time series. In this study, however, the ship manoeuvring motion was handled on a discrete time series because the ship was controlled by a digital signal. The ship maneuvering motion was analyzed using the discrete-time ARX model. This model estimated the current turning rate by Eq. (10) using the previous turning rates, the current rudder angle, the previous rudder angles and random noise.

Where z is time delay operator, nk is time delay in the system, e(t) is random noise and coefficient terms A(z) and B(z) can be expressed by Eq. (11) and Eq. (12). Where na and nb are the orders of the ARX model,

The orders of the model should be properly determined, because too higher-order increases complexity and too lower-order causes the system inaccurate. So, Akaike’s final prediction error(FPE) criterion(Akaike, 1969) was utilized. The optimal order is determined at the point where the FPE value rapidly dropped while changing the orders. The parameters

(d) PD controller

Generally, proportional-derivative(PD) controllers or proportional-integral-derivative(PID) controllers are widely used for steering of model ship. By the way, PD controllers have characteristics that the overshoot is smaller and the settling time is shorter than PID controllers(Lee et al., 1985). So, PD control was adopted to design the automatic steering system. Fig. 3 shows the process of a digital PD controller. Where, KP is proportional gain, TD is derivative time, Tf is derivative time constant and Ts is sampling time.

The designed controller of the slave ship repeatedly performs the following actions to follow the target course. First, calculates the error(e (z)) by comparing the target course(ψr) and the current course(ψ). Then, control variable(u(z)) is calculated by the proportional-derivative actions. The control variable(u(z)) is limited to –35 to 35 degrees(us (z)) by the saturator and entered into the ship manoeuvring motion model. Finally, the ship manoeuvring motion model outputs the turning rate(r), which changes the current course(ψ).

In addition, a first-order low-pass filter is applied as in Eq. (13) to prevent derivative kick caused by high frequency noise in derivative action.

where

Here, N is a coefficient for adjusting the bandwidth of the filter, and usually has a value between 8 and 20(Åström & Hägglund, 1995). It was set to 10 in this study.

To find the optimal values of parameters KP and TD of the digital PD controller, the relay feedback tuning method(Åström & Hägglund, 1984) was used. This method generates critical oscillation using a transport delay and a relay with an amplitude of d. Fig. 4 shows the process of the relay feedback tuning method.

From the critical oscillation graph, the critical period(Tc) and amplitude(a) could be found, and then the critical gain (Kc) is calculated by Eq. (15).

The parameters KP and TD of the PD controller is calculated by Eq. (16) and Eq. (17) using the Ziegler-Nichols tuning method(Ziegler & Nichols, 1942).

2.4 Speed controller

When the slave ship follows the master ship, the distance between the two ships should be kept constant for safety and communication stability. However, it is difficult to keep the speed constant even though the revolutions per minute(RPM) is kept constant, because the experimental boats are small as about 1 m and are easily affected by waves and winds. So, the speed controller was designed to keep the slave ship from 7 m to 12 m from the master ship.

Fig. 5 shows the flowchart of the slave ship speed controller. The distance between two ships(Ds) is calculated by the positions of the master ship(L1 , λ1) and the slave ship(L2, λ2) using middle latitude sailing method. Then, the controller changes the motor pulse width(Pm) according to the distance(Ds). The pulse width controls the motor RPM of the slave ship.

3. Experiments and results

3.1 Experimental setup

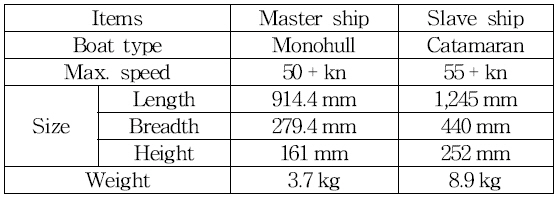

To verify the mathematical model of ship manoeuvring motion and the proposed system, sea experiments were conducted with two remodeled RC boats as shown in Fig. 6. The detailed specifications of the two boats are given in Table 2.

The systems of both boats are identical. Each boat had a propulsion system consisting of an electronic speed controller, brushless DC motor and propeller, and a steering system comprised of a servo motor and rudder. Both systems were controlled by pulse width modulation with a frequency of 50 Hz. To control the entire system, a microcontroller Arduino Uno and a microcomputer Raspberry Pi 3 Model B+ were equipped on the boat. These devices also performed boat-to-boat communications, sensor data collections, and route planning algorithms. Finally, a GPS sensor to measure the position of the boat and an radio frequency(RF) receiver to receive signals from a RF remote controller were equipped.

The experiments were conducted on the waters near Korea Maritime and Ocean University as shown in Fig. 7.

3.2 System identification results

The experiment was conducted as a turning test to estimate the orders(na, nb) and parameters(

The orders and parameters of the ARX model were determined using MATLAB system identification toolbox. The orders of the model were determined as na = 6 and nb = 6 using FPE criterion, and the corresponding parameters

Fig. 10 shows the turning rates obtained from the sea experiment(r) and calculated by the ARX model(rA). The coefficient of determination R2 of the obtained ARX model is about 0.9387, which means that the ARX model and the slave ship manoeuvring motion have a significance of about 94%.

To obtain the PD controller parameters KP and TD , the relay feedback tuning method was used. Adding a relay with an amplitude(d) of 10 and a transport delay of 1 second to the slave ship manoeuvring motion model, a critical oscillation graph with an amplitude(a) of 16.60 and a critical period(Tc) of 8 is generated as shown in Fig. 11.

The critical gain(Kc) was calculated by Eq. (15) as 0.767. The parameters of PD controller were calculated by Eq. (16) and Eq. (17) as KP = 0.614 and TD = 1.000. In sea experiment, KP and TD are tuned a little to prevent overshoot.

3.3 System verification results

The experiment was conducted to confirm that the slave ship autonomously follows the route of the master ship when the master ship is navigated manually. During the experiments, the Beaufort scale was 2 and the average wind speed was 1.8 m/s. But small wavelets on the surface were occurred due to the current to the southwest. Fig. 12 shows the experimental scene at sea. The average speed of the slave ship was 7.2 kn(3.7 m/s) and the master ship was 6.2 kn(3.2 m/s).

Fig. 13 shows that the slave ship autonomously follows the route of the master ship at a certain distance. The green and red lines represent each trajectory of the master ship and the slave ship. And the time indicated by the arrow shows the moment that the boat has passed through that position. The average speed of the master ship was 7.2 kn(3.7 m/s) and the slave ship was 6.2 kn(3.2 m/s).

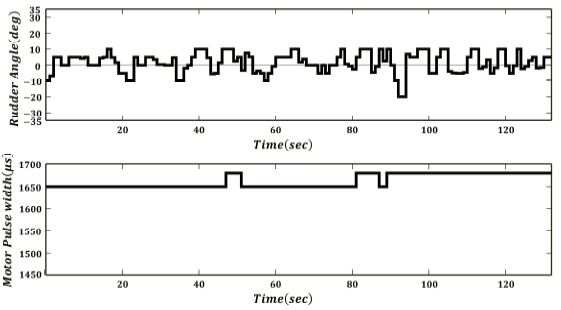

Fig. 14 shows the rudder angle and motor pulse width of the slave ship. The slave ship continuously used the rudder to follow the route of master ship. And the motor pulse width was autonomously changed to maintain a constant distance from the master ship.

4. Conclusions

This paper proposed connected ship navigation system. The system consists of a master ship and a slave ship. To implement the system, communication network, route planning algorithms and controllers were developed. The communication network was built using TCP/IP socket communication method so that the slave ship can receive the position of the master ship. Using the position of the master and slave ships, the route planning algorithms calculate the course of the slave ship by middle latitude sailing method. To design the automatic steering controller, Nomoto model was used as the mathematical model of the slave ship manoeuvring motion. Then, the ARX model was used to estimate the parameters of Nomoto model. Based on the identified model, the PD controller was designed by numerical simulations and sea experiments, and applied to automatic steering. And the speed controller was designed to keep distance between the two ships constant by controlling the motor RPM of the slave ship.

Sea experiments were conducted to verify the effectiveness of the proposed system. The experimental results revealed the effectiveness of proposed system by showing that the slave ship followed the route of the master ship autonomously while maintaining a constant distance from the master ship.

Future researches are as follows. Firstly, it is necessary to estimate the ship manoeuvring model more accurately by repeated experiments in the calm waters. Secondly, the system should be extended to use more than one slave ship. This can be a way to effectively deal with the various problems that ships may face in situations where MASS technology has not been fully developed.