|

|

| J Navig Port Res > Volume 43(2); 2019 > Article |

ABSTRACT

In 2001, about 20 years after the introduction of the standard buoys, the natural environment and maritime traffic flow changes in the waters near Korea and the necessity of improvement of the AtoN (Aids to Navigation) maintenance was suggested. The IALA provides guidelines for maintenance and management of AtoN, and Korea provides guidelines for the management and operation of standard buoys by means of the Enforcement on the AtoN laws. The objective of this study was to investigate the installation status and the repair status of the standard type buoys by sea area in order to improve the management and operation of the steel standard buoys. In addition, a survey was conducted on the improvement of the steel buoy fouling and the improvement of the lifting inspection cycle towards on the AtoN managers and producers of the representative authority by sea area. In the case of LL-26 (M) buoy type, the standard type buoy installation status of Korea in 2017 was 57.1%, and the LL-26 (M) type was 58.9% showing the highest repair rate. According to the results of the survey on buoys fouling, 51.2% were caused by the attachment of shellfish, and 43.2% were caused by bird feces. The results of the survey on the improvement of the regular buoy inspection cycle showed that the measures are to maintain the current inspection period of 2 years regardless of the characteristics of the sea area (water depth, inside and outside port, buoy size, etc.).

According to the Standardization and Operation Regulations of MOF(Ministry of Oceans and Fisheries, 2001), there were 19 types (11 kinds of light buoys and 8 kinds of buoys) in the standard buoys, and 6 more buoys such as buoys for small boats were added in 2015, therefore there are 25 standardized buoy types at the moment. As a result of 20 years after the adoption of the standard buoys in 2001, the necessity of improvement of the standard buoy types reflecting the changes in the natural environment and the sea traffic flow has been raised. Also, the problem of safety accidents such as worker's narrowing of work space was raised, and the necessity of improvement of the standard type buoys reflecting the natural environment and management operation status by sea area emerged.

From 2011 to 2015, there were 381 cases of standard buoys' accidents and 5 types of damage / loss / deviation / displacement / etc., among which 242 cases (79.1%) were caused by buoy damage(MOF, 2017a). As a cause of buoys' damage was due to by external force / equipment failure / ship collision / weather deterioration/ etc.. The equipment failure accounted for 162 (60.5%) out of 242 damages, which was the most frequent cause of damage. Therefore the need for research on the improvement plan of the buoys management operation was suggested.

The IALA(International Association of marine aids to navigation and Lighthouse Authorities) guidelines for maintenance and management of steel buoys are divided into land and base stations. Onshore maintenance includes gas discharge, blast cleaning of buoy surface / superstructure / repair of buoy appendages and instructions for buoy painting. In addition, maintenance at the base station provides information on the removal of marine organisms and the repair of buoy surface / superstructure / repair of buoy appendages(IALA, 2009; IALA, 2013a; IALA, 2013b; IALA, 2017). According to the IALA recommendation, the guidelines for the operational aspects of the management and operation of steel buoys are presented in the Enforcement Decree of The Navigational Aids Act(KMGL, 2015, KMGL, 2017; KMGL, 2018).

In this paper, we investigate the status of the standard buoys and the damage of the offshore buoys in the Korean waters in order to improve the antifouling of the standard buoys management scheme. In addition, a questionnaire survey was conducted to identify the ways to improve the pollution by the steel buoys debris and to improve the lifting overhaul inspection cycle, and to provide a basis for the improvement of management and operation of standard buoys.

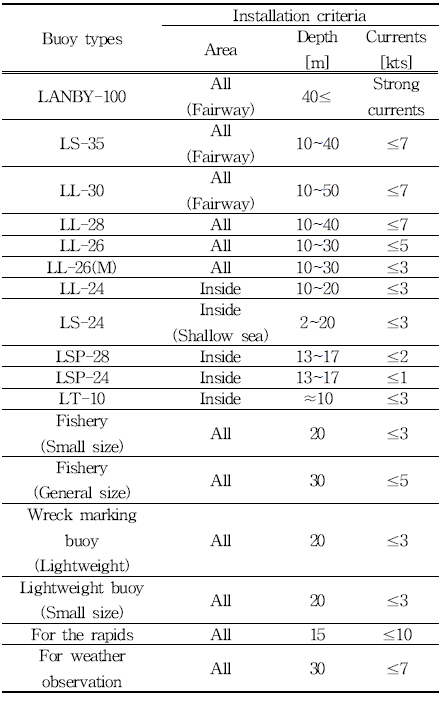

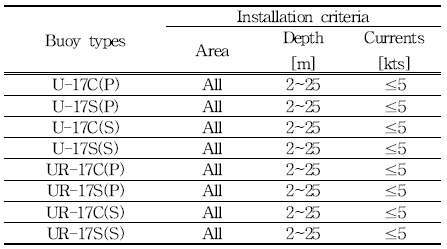

As of 2017, there are 17 kinds of lighted buoys and 8 kinds of unlighted buoys in Korea, and the installation criteria of lighted buoys and unlighted buoys according to natural environment conditions and traffic conditions are as shown in Table 1 and 2(KMGL, 2015b).

LANBY-100 can be installed in the strong currents zone of 40m or more in depth, and LS-35/ LL-30/ LL-28 and ocean weather observation buoy can be installed in the flow of less than 7 knots. A buoy type that can be installed on the main traffic routes of less than 7 knots is the LS-35 and LL-30 type lighted buoys. Table 2 summarizes the buoy types that can be installed at the sea area with a depth of 2~20m and in the flow of less than 5 knots.

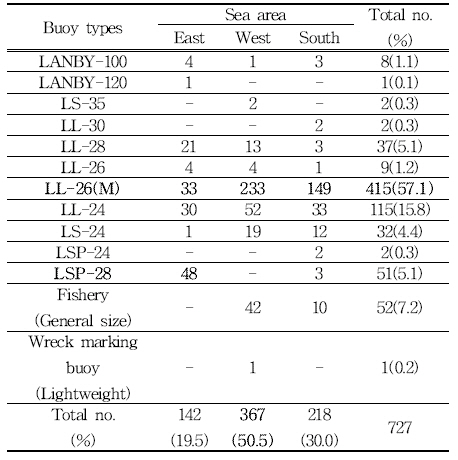

Table 3 shows the state-of-the-art installation of the state-owned standard type buoys by sea area (MOF, 2017b). The LL-26 (M) type buoy in the whole sea area accounted for about 57% of the total, showing the highest rate. In the east sea region, LSP-28 was found to occupy the largest number of buoys along with the LL-26 (M) buoy type. By sea area, it was found that most of the sea buoys in the west sea were occupied by 50.5% of the total, and the installation rates of the south and east sea were about 30% and 19.5%, respectively.

Annual repair and inspection cards were collected for 3 years(2015~2017) in order to investigate the status of standard type buoys fouling, and the repair rate and repair items were analyzed by sea area and buoy types(MOF, 2017c).

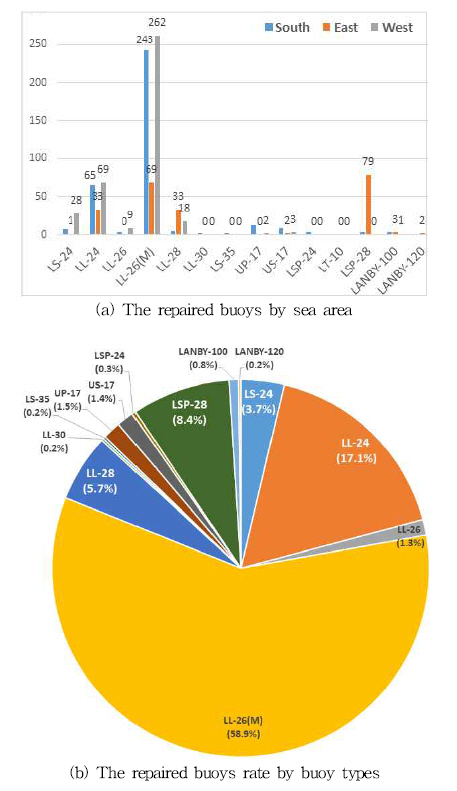

LL-26 (M) was the most commonly used buoy type in the whole watershed area, with 262 in the west sea area, 243 in the south sea area, and 69 in the east sea area. The buoy type, which showed the next highest repair rate, was the LSP-28, which had a high repair rate in the east sea with 79 units. The LL-24 buoy type was followed by LL-26 (M), with 69 in the west sea, 33 in the east sea, and 65 in the south sea. The results of the repair rate according to the buoy type and by the sea area are shown in Fig. 1(a), (b).

Table 4 summarizes the repair status by buoy type. The LL-26 (M) type occupied about 58.9% of the whole area, and the highest repair rate was obtained. In the west sea, 392 buoys were repaired, and the repair rate in south and east sea were 37% and 22.8%, respectively.

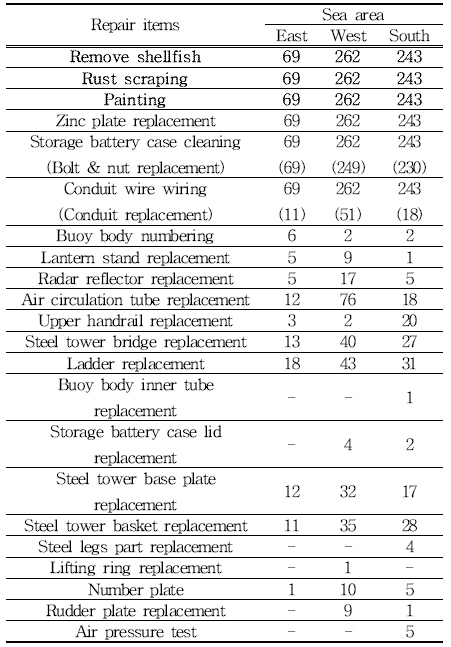

Table 5 summarizes the repair items of the LL-26 (M) buoy type, which has the highest repair rate at 58.9% in the whole sea area. The top six items were the most frequent repair items such as removal of shellfish, rust scraping, painting work, replacement of zinc plate, cleaning of battery case(replacing bolts and nuts), wiring of conduits.

Among the most frequent repair items, repairs related to the steel buoys fouling are the removal of shellfish, the rust scraping, the replacement of zinc plates. The frequency of buoy repair and inspections was performed at intervals of about once every two years based on Enforcement Decree of the Navigational Aids Act: Regulations on Management and Operation of Vessels for Navigational Aids Business Use(KMGL, 2017).

Fig. 2 is the LL-26 (M) buoy type, which is the most installed in the whole waters of Korea, and shows the condition of the shellfish attachment of Busan New Port No. 2 lighted buoy during the lifting work performed for the regular inspection in 2017.

The purpose of this study is to find out the actual condition of the steel standard buoys in Korea and to find out the improvement plan. Therefore, the government officials in the regional maritime affairs and buoys maker were surveyed as shown in Table 6. The survey was conducted between August 2017 and January 2018. Questionnaires were conducted through direct interviews and e-mail. A total of 41 respondents were surveyed, and the majority of respondents (66.7%) were experts who had worked for more than 11 years(Questionnaires missing a description of career were excluded).

The survey results of this study are as follows.

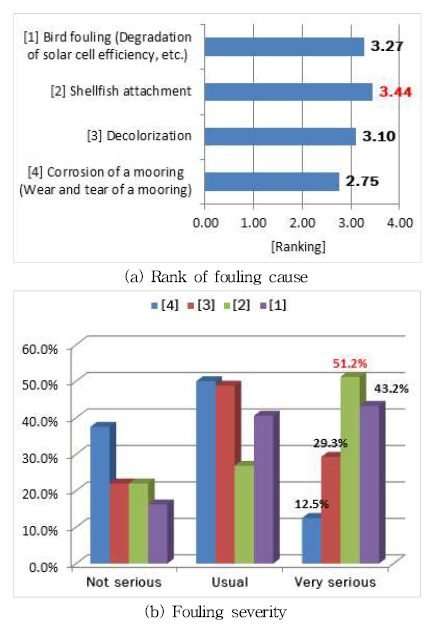

First, 41 specialists who responded to the questionnaire were asked about the seriousness of corrosion (abrasion), decoloration, attachment of tidal flats and deterioration of solar cell efficiency due to contamination of bird droppings. As shown in Fig. 3 (b), 51.2% of shellfish attachment among the four fouling sources were found to be very serious, followed by 43.2% of pollution caused by avian excreta. As a result of measuring the priority level of the degree of severity of the four pollution factors, the factor of the shellfish attachment (3.44) was the most serious, followed by the decrease of the solar cell efficiency due to pollution of the bird excrement (3.27) > decolorization (3.10) > wear and tear of a mooring (2.75) in that order as shown in Fig. 3 (a).

Second, we conducted a survey on the degree of corrosion (abrasion) of the mooring line (KMGL, 2018), which is the lowest level in the ranking of the degree of pollution factor, but confirmed at the periodic inspection at the 2-year cycle. In other words, the expert group responded that the abrasion rate of steel buckle wear was 23.9% on average compared with the first one during the periodical inspection for two years. According to results by Regional Office, Busan Regional office (east sea) responded that the average degree of corrosion was the highest at 30.8%, followed by Pyeongtaek Regional Office (west sea) at about 20.0% and Yeosu Regional Office (south sea) at about 10.0%. According to the response, the degree of corrosion of the Busan Office coastal waters (east sea) was found to be the most serious on the basis of the current 20% corrosion tolerance standard.

However, since this qualitative analysis is not enough to judge the extent of corrosion by the sea area objectively and scientifically, it is necessary to take measures to estimate the quantitative corrosion degree of steel buoys at regular inspection. In addition, it was investigated that there were other damage and damage factors due to collision of ships, tangling of fishing gears, different degrees of corrosion due to different current flow and seabed conditions.

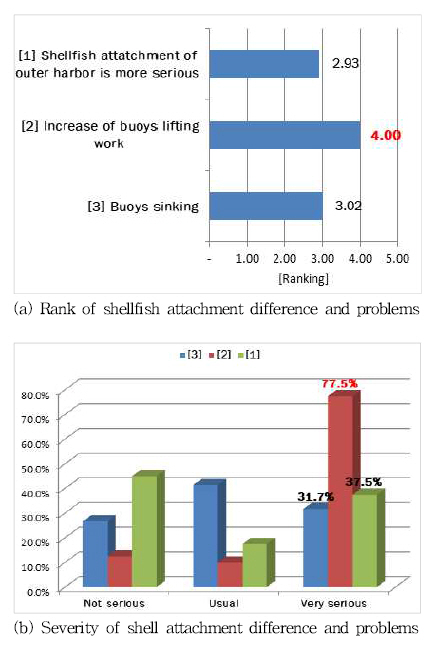

Third, we conducted a more detailed opinion on the problem of shellfish attachment, which is one of the most serious factors of steel buoys fouling. As shown in Fig. 4, the effect of the shellfish attachment is more serious for buoys sinking, more work time in buoy lifting work. 77.5% of respondents strongly expressed their opinion at "Very serious", as a result of the fact that it takes more time to work on lifting the steel buoys. As a result, it was the most severe that the more work time for buoy lifting (4.00) among the three effects.

In addition, the problems associated with the attachment of other shellfishes are as follows: First, it takes considerable time and manpower to remove the shellfish from the sea for the inspection, and points out the risk exposure of marine work. Second, there was a concern about the environmental pollution problem during the removal of the shellfish and there was an answer that it is necessary to prepare guidelines for removing shellfish to solve them.

The lifting inspection period of steel buoys in Korea is currently 2 years. On this, we surveyed opinions on necessity of the adjustment on appropriate lifting period for 1) Inside and Outside of the port, 2) Large buoys and General buoys, and 3) Shallow water and Deep sea area.

First, as shown in Table 7, it was found that in all situations, there was no consensus on the necessity of introducing different regular periodic inspection cycles according to the above three situations. In other words, it was found that it is not necessary to adjust the regular inspection cycle regardless of 1) Inside and Outside the port, 2) Large and General Buoy, and 3) Shallow and Deep water depth.

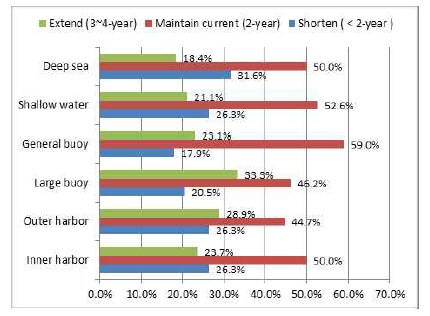

Second, as shown in Fig. 5, the response of expert group was gathered to compare with the current two-year inspection cycle. First, it was shown that the current two-year cycle should be maintained in the Deep-water area (50.0%), Shallow-water area (52.6%), General buoy (59.0%) and Inner harbor (50%). Next, 33.3% and 28.9% of the respondents answered that it should be extended to 3~4 years for the Large buoy and Outer harbor buoys. 31.6% in the Deep-water area, 26.3% in the Shallow-water area, Outer harbor and Inner harbor answered that it is need to shorten less than two years.

As shown in Fig. 5 results, the necessity of adjusting the buoy inspection cycle shown was shown that the adjustment period is not necessary in all situations. According to the survey, 50% and 44.7% of the respondents in Inner and Outer port agreed to maintain the current two years, respectively. 28.9% of respondents answered that they need to extend the inspection cycle to three to four years in Outer port. In General and Large buoys, 59% and 46.2% respectively agreed to maintain the current two years, followed by 23.1% and 33.3% to three to four years. In the case of Shallow water and Deep water depth, 52.6% and 50% of the current two year maintenance opinions, and 26.3% and 31.6% of the opinion that shorten the inspection period to less than two years were shown.

Since the adoption of the standard type buoys has been about 20 years since the introduction in 2001, there has been a need to improve the standard type buoys due to changes in the natural environment of the coastal waters and changes in the maritime traffic flow. According to the statistics of the standard buoy accidents occurred in the last five years (2011~2015), buoys damage is for about 80% among all accident types. Korea's AtoN are maintained by sea area divided into east sea, west sea, and south sea. The representative agencies are performing buoy operation management for each sea area, and the AtoN marker association is in charge of the production of standard buoys.

In this paper, we have investigated the installation status of the standard type buoys and the buoy condition of each sea area in order to improve the management method of the standard buoys. In the case of the LL-26 (M) type buoy, which occupied the largest installation rate in the entire waters of Korea, 415 (57.1%) out of the total 727 were installed in 2017. Next, the LL-24 buoy type occupied 115 (15.8%) and showed the highest installation ratio with the LL-26 (M) buoy type. The LL-26 (M) type was the highest repair rate in 574 (58.9%) out of 974 from the total repair examinations conducted for 2015~2017 years.

In addition, we conducted a survey on awareness of the measures to improve the steel standard buoys fouling maintenance and the improvement of the lifting inspection cycle. The results of the survey for the steel standard buoys fouling pollutants showed that the fouling due to the shellfish attachment, the fouling from the bird excrement were serious, and the shellfish attachment showed the highest fouling factor with 51.2%. In addition, it was suggested that the problem caused by the shellfish attachment is that more time is required for the lifting work. The results of the survey on the improvement of the inspection period of buoys were examined that the current two-year periodic inspection cycle is appropriate in all situation(the Inside and Outside the port, the Large buoy and the General buoy, Shallow water and Deep area).

For further study, since the evaluation of the pollution and the improvement of the lifting inspection cycle is a result of the qualitative evaluation on the buoy maintenance manager and the maker, it is necessary to prepare a plan to improve the operation of standard buoys management based on objective data (such as deterioration of paint visibility, wear and tear rate of mooring appendages, attachment condition of shellfish after the buoys installation).

- TOOLS

-

METRICS

-

- 0 Crossref

- 0 Scopus

- 1,673 View

- 10 Download

- Related articles

-

A Study on the Safety Improvement of Vessel Traffic in the Busan New Port Entrance2022 August;46(4)

A Study on the Necessity of Limitation for Legal Liability in Marine Accidents2010 April;34(3)

Questionnaire Survey on the Risk Perception in the Istanbul Strait2010 September;34(7)

PDF Links

PDF Links PubReader

PubReader Full text via DOI

Full text via DOI Download Citation

Download Citation Print

Print